Over twenty five years of experience with pulley lagging research and manufacturing has resulted in continuous advances in rubber blends tile designs and tread patterns.

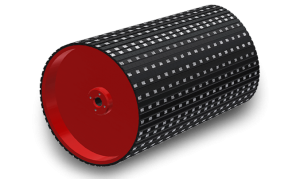

Weld on ceramic pulley lagging.

After removing the pulley transporting it to replace lagging causes downtime costs increased.

Since the retainers are already in place replacement of worn lagging is quicker and easier.

This eliminates the wide gutters present in conventional weld on lagging products and also helps minimize problems associated with vibration cleaner chatter and overall belt cleaner compatibility.

This eliminates the wide gutters present in conventional weld on lagging products and also helps minimize problems associated with vibration cleaner chatter and overall belt cleaner compatibility.

Richwood lagging systems are an effective long term solution to conveyor drive problems.

Eliminating drive slippage is of primary importance for efficient conveyor operations.

In fact with 80 tile coverage it features the highest coefficient of friction available in lagging materials two to three times the friction of rubber in wet muddy or dry conditions.

Large ceramic tile is molded into the diamond section providing an increased coefficient of friction compared to diamond pattern rubber lagging.

Features and benefits available in rubber and ceramic.

It provides very good performance in dry wet or wet muddy applications where slippage can occur while also offering the excellent wear life of ceramic tiles at an affordable cost.

Flex lag diamond ceramic lagging flex lag diamond ceramic is specially designed to deliver the performance advantages of ceramic lagging at a much more affordable price.

Flex lag weld on pulley lagging features a patented gear tooth design.

Flex lag medium ceramic lagging featuring 39 coverage offers a lagging option between diamond pattern ceramic 13 coverage and full ceramic 80 coverage.

Few days 3 5.

Hiring cranes is very expensive.

.jpg)